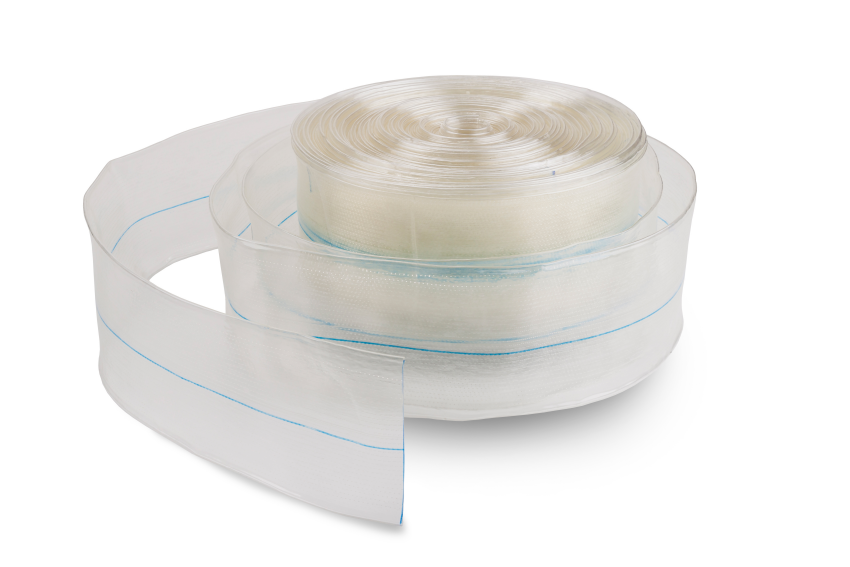

Aeration membrane PUM 68

The PUM 68 aeration membrane is a polyurethane membrane with specific openings allowing for air release in the form of fine bubbles ensuring aeration of the required medium, usually mixed liquor at wastewater treatment plants.

If there is sufficient volume of blown air and optimal tank bottom coverage with aeration elements, the even bubble distribution results in the medium stirring and sludge is maintained in suspension.

Given the properties of the applied polyurethane, our membrane is highly flexible and resistant which ensures, along with the design and density of perforation, high resistance to the chemical and microbial composition of wastewater as well as automatic drainage and resistance to incrustation.

The membrane features a long service life. Very good oxygen utilisation is reflected in economic operation of aeration systems fitted with these membranes.

Properties:

- Wide aeration operating range

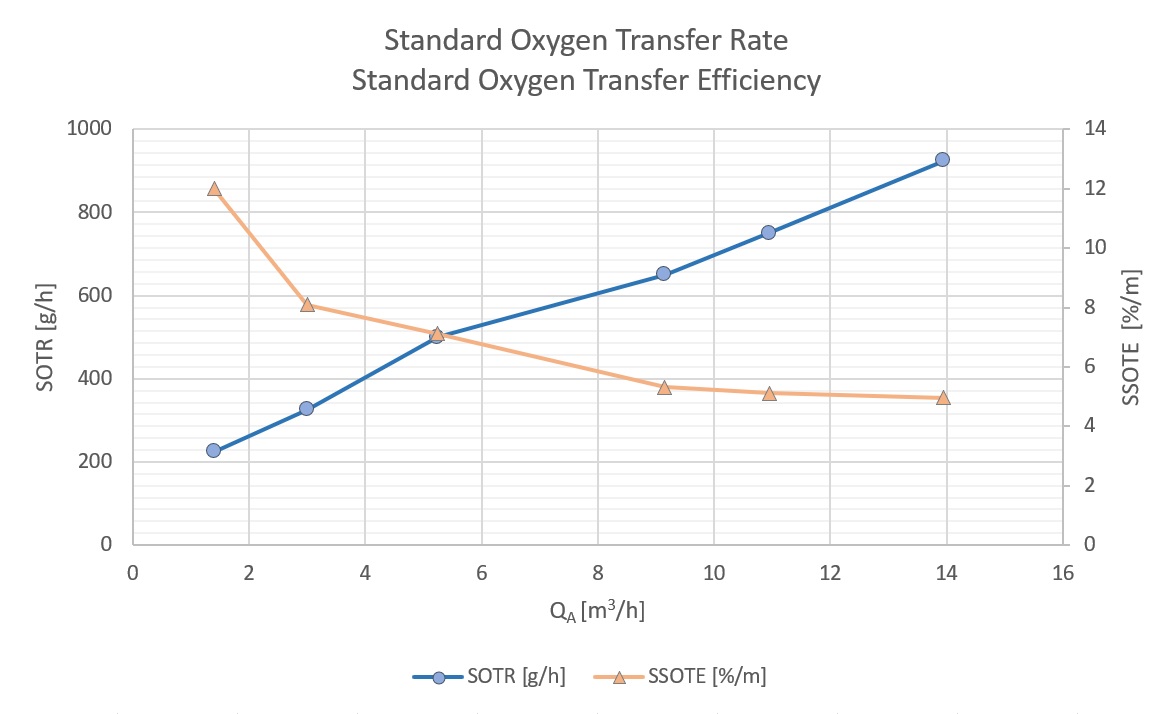

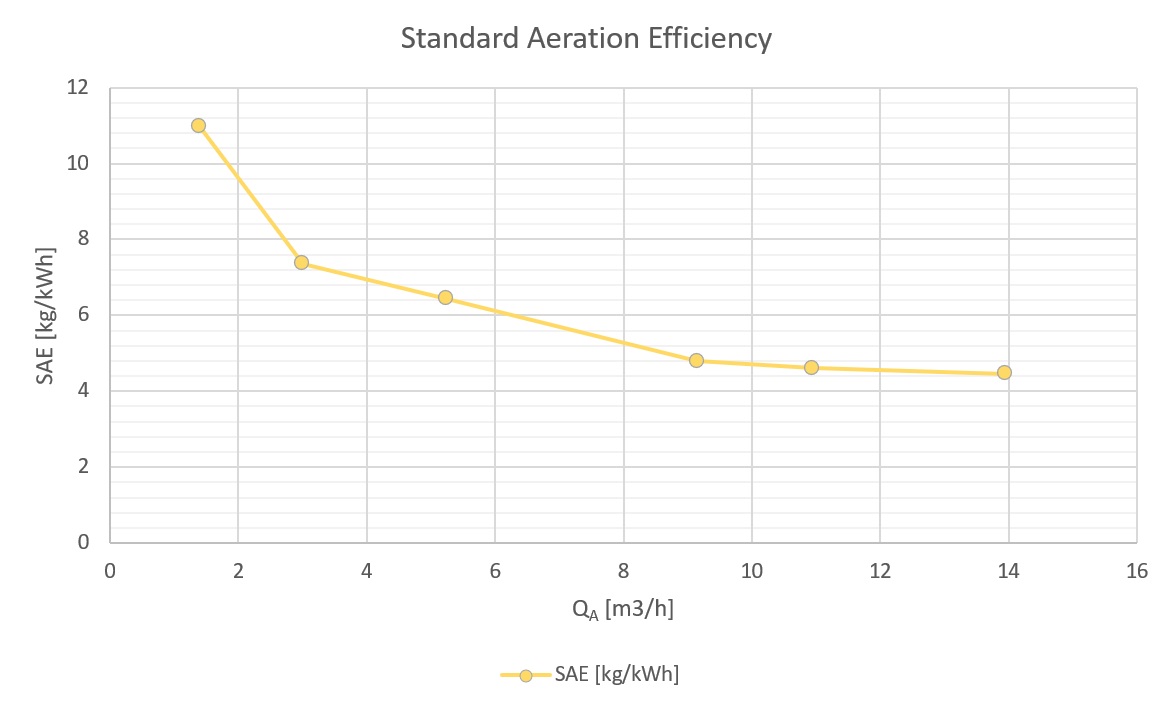

- High oxygen input and oxygen transfer efficiency

- Low pressure loss

- High tear-resistant and abrasion-proof

- Good resistance to oil, gasoline and chemicals common in municipal waste water

- High resistence to microbe and incrustation

- Long service life

|

Technical parameters of membrane PUM 68 | |

| material | polyurethane | |

| outer diameter | 68 mm | |

| recomended air flow rate | 1,5 - 10,0 Nm3/h.m | |

| optimal air flow rate | 5,0 Nm3/h.m | |

| pressure loss | 4,0 - 6,5 kPa | |

| standard aeration efficiency | 4,6 - 11,0 kg/kWh | |

| standard oxygen transfer efficiency | 5,1 - 12,0 %/m | |

| recommended temerature range | 10 - 35 °C | |